www.737cbt.co.uk

Truly Interactive Software

Design Philosophy

After completing various commercial aircraft ratings over the years it became obvious there is a need for fully interactive aircraft systems training software. Traditional CBT (computer based training) seemingly offers very limited interactivity and is mainly just static slides (and a lot of them!) as per the aircraft manual.

Thus the aim of this suite of software is to provide highly accurate system models with full interactivity.

Aircraft training / tests are always very demanding, intensive and stressful if you are under prepared. The best way to reduce that pressure and make training / tests more enjoyable is to be well prepared, always prudent as your career can be influenced by the result!

Thus our fully interactive software approach provides you with the ability to prepare yourself in advance for that new type rating, recurrent training, or just refreshing your knowledge.

Run through normal operating procedures, inject faults into the systems making your own choice of real-life event scenarios, then run through non-normal procedures with the QRH (Quick Reference Handbook) just as you would in the simulator or when flying the line.

Functionality

The best way to get a 'feel' what the software does is to view the 'Hydraulics and Flight Controls' demonstration video. In essence it accurately models the hydraulic 'A', 'B' and standby system, hydraulic control panel, hydraulic flight control panel and all their associated switches / lights.

This is all shown by the main colour coded hydraulic schematic which includes the Reservoirs, Pumps, Valves, LE Slats / Flaps, TE Flaps, Rudder, Standby Rudder, Yaw Dampers, left and right Thrust Reversers, Ailerons and Elevator with associated manual reversion / WTRIS. Normal and Alternate Braking, Flight Spoilers / Ground Spoilers, Landing Gear, Nose Wheel Steering, Alternate Nose Wheel Steering and Autopilots A / B.

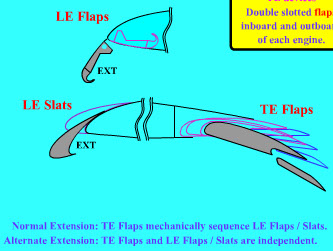

Separate windows provide a Master Caution / Recall panel, Hydraulic Quantity / Pressure indications and a Flap lever. The Leading edge (LE) flaps / slats and TE flaps window shows the dynamic movement of the wing leading and trailing edge surfaces together with the LE Annunicator Panel and TE Flap Indicator Gauge and associated lights. Both the normal and alternate operation of the wing surfaces has been modelled which includes Autoslat operation and TE Load Relief functionality.

The indicator lights and switches on the hydraulic panel and flight control panel can be superimposed and operated from the main schematic as desired. A whole host of technically information related to the components of the system can be viewed by using the 'i' for information feature.

The 'Electrical System' also has a colour coded schematic, relevant electrical control panels and functions in the same manner as the 'Hydraulics and Flight Controls' module.

.

Quality Look

We believe that learning is 90% visual.

The main system schematics, cockpit panels and all the windows and their content have been designed using 'vector' graphics. This means you can zoom in / out without losing any visual quality, ideal when using an overhead projector when training others.

The software and graphics has been implemented in such a way enabling it to run without any issues on older slower machines as well as the latest higher speed of computer processors / graphics cards.

.

Inject Faults - Hydraulics / Flight Controls

So what faults can you inject into the system? The 'Fault' menu is designed to allow you to set the aircraft into a whole host of configurations thus covering the QRH drills.

Hydraulic Pumps.

Either left or right engine driven or electrically driven hydraulic pumps can be failed. An overheat is also possible for the electric hydraulic pumps.

Flight controls.

Both single and dual channel failures for Speed Trim, Mach Trim and AutoSlat can be injected showing the different responses from the Master Caution / Recall system.

LE (Leading Edge) Flaps / Slats

LE uncommanded motion. LE Slat failure to move and failure while running, LE Flap failure while running.

TE (Trailing Edge) Flaps

TE uncommanded motion, TE left/right skew, TE asymmetry.

Hydraulic Leaks

Both 'A' / 'B' major leaks, 'A' Engine Pump Leak, Standby system leak.

Other failures and triggers.

Alternate flaps switch failure, flap lever cable break, an AutoSlat signal triggering AutoSlat operation, a Flap Load Relief trigger signal, a Rudder FFM (Force Fight Monitor) signal to automatically trigger Standby rudder and a LGTU (Landing Gear Transfer Unit) trigger to simply show transfer to the 'B' system hydraulics when retracting the landing gear after loosing a left engine on takeoff.

.

'i' for Information

'i' for information provides a whole host of technical information regarding the system. Just select it to 'on' from the Options / View menu then rollover the relevant 'i' icon and a pop-up window appears.

Hydraulics and Flight Control Examples:

.

Electrical System Examples:

1

3

2

1

3

2

'Light' Information

''Light' information gives technical information regarding the panel lights. Just select it to 'on' from the 'Options / View' menu then rollover the relevant light and a pop-up window appears.

Hydraulics and Flight Control Examples:

Electrical System Examples:

.

1

3

2

1

3

2

Summary

We were delighted to announce the release of our first module 'Hydraulics and Flight Controls' and have now added the fully intearctive 'Electrical System'. The next module will be 'Air Systems and Pressurisation'.

We are also developing detailed video's reviewing the fundamentals of each aircraft system (as featured in our software) to complement the family of interactive learning software we are creating.

Our aim is to provide the highest-quality training experience to renew / enhance your knowledge.

We believe our software offers pilots the most advanced fully interactive type-rating training software.

Probably the industries most accurate fully interactive systems software developed by commercial pilots for commercial pilots.

Software to provide that required practical operational perspective.

.

Technical Hints

Practical 'technical knowledge hints' are also given in various windows. For example, within the Flaps / Slats window you will see "Normal Extension: TE Flaps mechanically sequences the LE Flaps / Slats". This is a reminder what triggers the movement of the LE Flaps / Slats when using the normal flap system.

.

Inject Faults - Electrics

The 'Electrical System' does not have a dedicated 'Fault' menu like the 'Hydraulics and Flight Controls' but is still designed to allow you to set the electrical system into a whole host of configurations thus covering the QRH drills.

This is achieved simple by toggling the components within the system on / off from the 'Options' sub menu's i.e.' AC Power Sources', 'DC Power Sources', 'Aircraft' and 'Other'.

Electrical Components that can be switched on / off.

GRD Power Available, APU running, Inverter, IDG1, IDG2, TR1, TR2, TR3, Main Battery Charger, AUX Battery Charger, ENG1 running and ENG2 running.

.

Other failures and triggers.

APU Overload, DC / STBY control fault and GS capture in APP mode.

.

Design Philosophy

Functionality

Quality Look

Inject Faults - Hyd / Flt Cont

'i' for Information

'Light' Information

Summary

Technical Hints

Inject Faults - Electrics

INFO

Information

If you have any queries, please contact us.

Truly Interactive Software

Copyright www.737cbt.co.uk 2021

Disclaimer.

The software content and its themes is NOT to be used operationally. Always refer to your official company aircraft training manuals / aircraft manuals as the definitive source of information.